Is Your Business Safe? The Importance of Regular Commercial Electrical Maintenance

January 5, 2026

Electricity is the backbone of modern businesses, powering everything from lighting and HVAC systems to computers, machinery, and security devices. Despite its essential role, many commercial property owners overlook routine electrical maintenance, assuming that systems will function properly until a problem arises. This reactive approach, however, can be costly and dangerous. Electrical failures are not just inconvenient—they can disrupt operations, damage equipment, and even create life-threatening hazards for employees and customers. In today’s competitive business environment, ensuring the safety and reliability of electrical infrastructure is no longer optional—it’s critical.

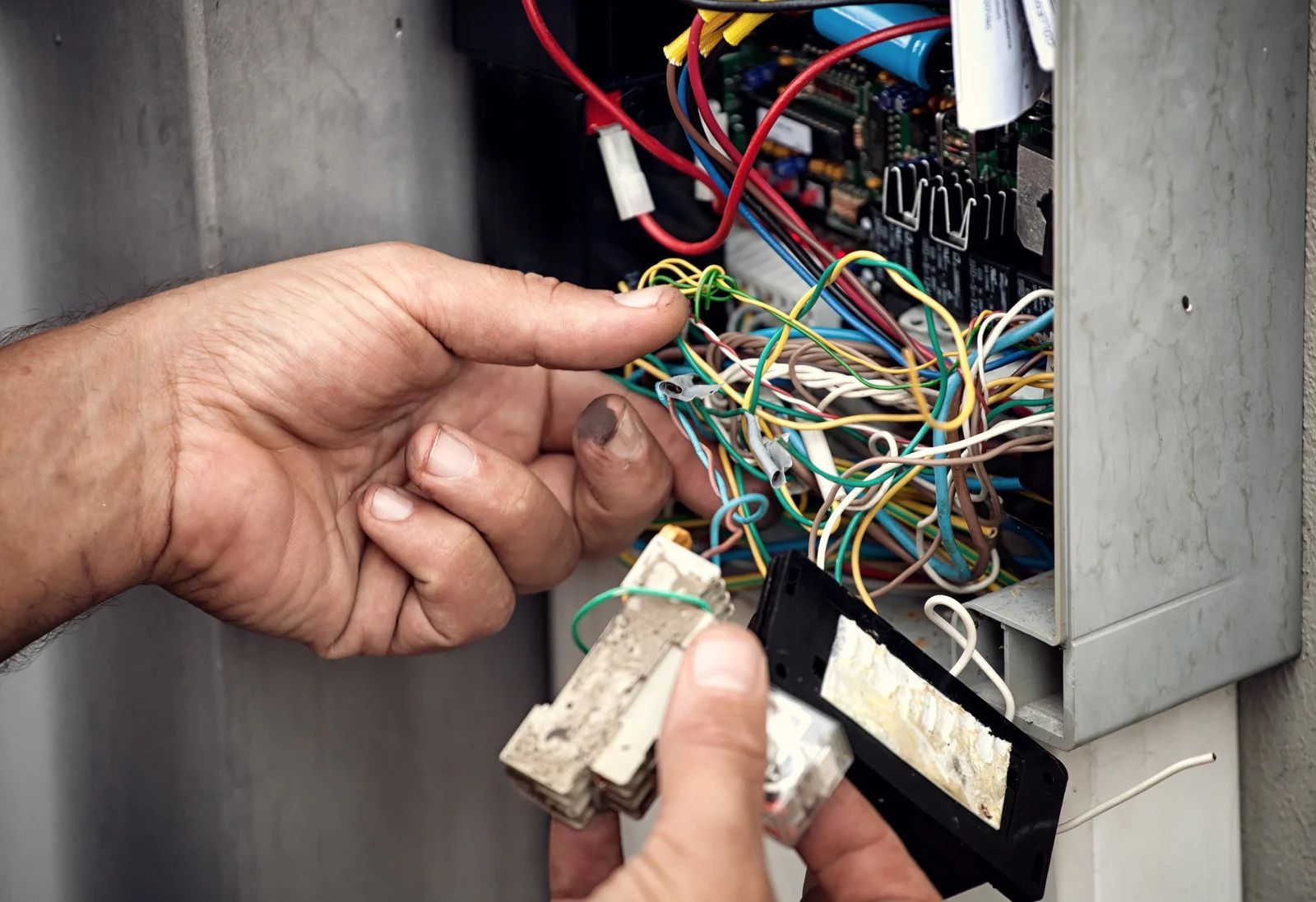

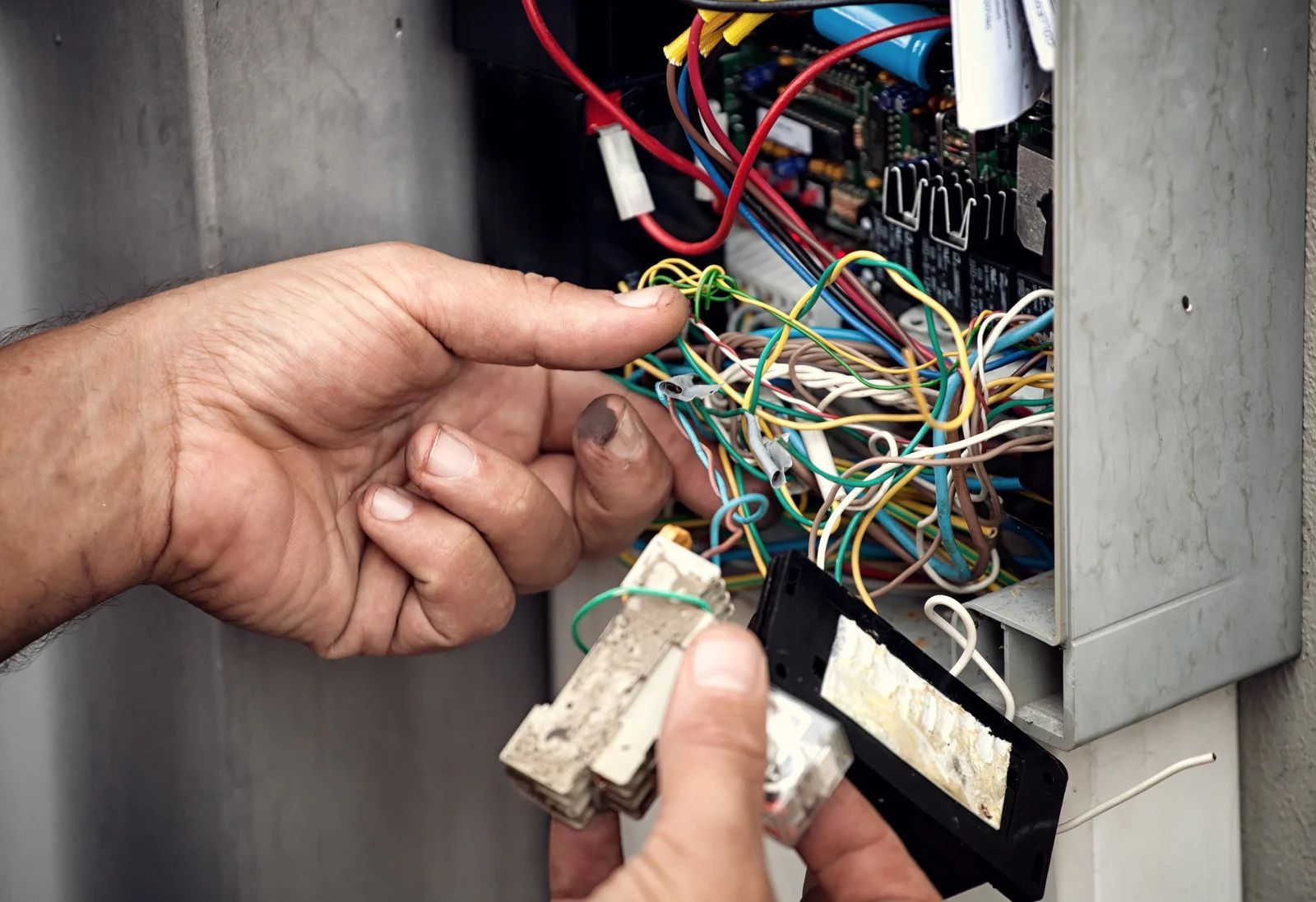

Regular commercial electrical maintenance involves systematic inspections, testing, and upgrades of wiring, panels, breakers, and related components. By proactively addressing potential issues, businesses can prevent outages, reduce fire risks, extend equipment life, and maintain compliance with safety codes. This proactive strategy not only protects employees and property but also supports uninterrupted productivity, saving businesses time and money in the long term. In this blog, we will explore why commercial electrical maintenance matters, the key benefits, common risks, practical best practices, and how to create a sustainable maintenance plan that safeguards your business and ensures operational continuity.

Understanding Commercial Electrical Maintenance

What It Entails

Commercial electrical maintenance is more than occasional inspections. It encompasses thorough evaluations of electrical panels, wiring systems, circuit breakers, outlets, emergency lighting, surge protection, and backup power systems. Maintenance also involves testing for compliance with local safety codes, identifying aging or overloaded circuits, and replacing faulty components before they fail.

Types of Maintenance

- Preventive Maintenance – Scheduled inspections and servicing to identify and fix issues early.

- Predictive Maintenance – Using diagnostic tools and monitoring equipment to predict potential failures.

- Corrective Maintenance – Addressing identified issues promptly to avoid operational disruption.

Real-World Scenario

A mid-sized manufacturing company experienced a complete shutdown because of an overloaded circuit that could have been identified through preventive maintenance. The outage not only halted production but caused significant financial loss and delayed client deliveries. This example highlights the importance of proactive electrical care.

Risks of Neglecting Electrical Maintenance

Fire Hazards

Faulty wiring, overheating circuits, or improperly installed components are among the leading causes of commercial fires. Fires can result in devastating property damage, legal liabilities, and potential loss of life.

Equipment Damage

Electrical surges, power fluctuations, and outdated wiring can damage sensitive equipment like computers, manufacturing machinery, and HVAC systems. Equipment repairs and replacements are expensive, often exceeding the cost of regular maintenance.

Operational Downtime

Unexpected electrical failures can halt business operations entirely, leading to lost productivity and revenue. Even a short outage in a retail store, office, or warehouse can disrupt critical workflows and customer service.

Compliance and Liability Issues

Businesses must comply with local and national electrical codes. Neglecting maintenance can lead to violations, fines, and legal liabilities, particularly if an electrical failure results in injury or property damage.

Key Benefits of Regular Electrical Maintenance

- Enhanced Safety:- Routine inspections identify potential hazards like exposed wires, overloaded circuits, or malfunctioning equipment, significantly reducing the risk of electrical fires and accidents. A safe working environment protects employees and reinforces organizational reputation.

- Improved Operational Efficiency:- Well-maintained electrical systems run more efficiently. Properly functioning lighting, HVAC, and machinery reduce energy consumption, lowering utility bills and minimizing environmental impact. Businesses experience smoother workflows without unexpected interruptions.

- Longevity of Equipment:- Regular maintenance extends the life of electrical equipment and infrastructure. Replacing worn-out parts before failure prevents costly breakdowns and ensures critical systems remain operational longer.

- Cost Savings:- Preventive maintenance reduces emergency repair costs, avoids fines for code violations, and prevents losses associated with operational downtime. Investing in regular care saves money in the long term compared to reactive fixes.

- Compliance Assurance:- Regular checks help maintain adherence to OSHA standards, local building codes, and insurance requirements. Compliance reduces legal risks and enhances credibility with clients, partners, and stakeholders.

Common Challenges in Maintaining Commercial Electrical Systems

Aging Infrastructure

Many commercial buildings operate on outdated wiring and systems. Older electrical infrastructure is more prone to failure and may not meet current safety standards.

Limited In-House Expertise

Smaller businesses may lack qualified personnel to perform comprehensive electrical maintenance. This gap can lead to overlooked issues and inadequate safety measures.

Budget Constraints

Some businesses delay maintenance due to perceived costs. However, skipping maintenance can result in more substantial financial losses from equipment damage, downtime, and regulatory fines.

Complex Systems

Modern commercial facilities often have complex electrical setups, including lighting controls, backup generators, and smart building technologies. Managing maintenance across these systems requires expertise and precise planning.

Best Practices for Commercial Electrical Maintenance

- Schedule Regular Inspections:- Establish a maintenance calendar that includes annual, semi-annual, and quarterly checks depending on equipment usage and building size. Professional electricians should examine panels, outlets, breakers, and wiring during each inspection.

- Perform Load Testing:- Overloaded circuits are a common source of failure. Regular load testing ensures circuits operate within safe parameters and identifies areas needing capacity upgrades.

- Upgrade Outdated Systems:- Replace old panels, wiring, and breakers to prevent hazards. Upgrading systems to meet modern safety standards improves reliability and reduces energy consumption.

- Implement Predictive Monitoring:- Use advanced monitoring tools to detect anomalies in current, voltage, or power quality. Predictive maintenance allows early intervention before issues escalate.

- Educate Employees:- Train staff on electrical safety practices, such as avoiding overloading outlets, reporting unusual sparks or smells, and understanding emergency shutdown procedures. Employee awareness is a critical line of defense against electrical hazards.

- Maintain Detailed Records:- Keep a comprehensive log of inspections, repairs, upgrades, and replacements. Documentation aids in compliance, insurance claims, and identifying recurring issues.

Creating a Sustainable Maintenance Plan

Assess Current Systems

Begin by evaluating your electrical infrastructure. Identify high-risk areas, equipment prone to failure, and any code compliance gaps.

Define Maintenance Goals

Set clear objectives, such as reducing downtime, preventing fire hazards, or improving energy efficiency. Goals guide scheduling and resource allocation.

Partner with Professionals

Hire licensed and experienced commercial electricians for inspections, repairs, and upgrades. Professional oversight ensures thorough assessments and adherence to safety standards.

Establish a Budget

Allocate resources for routine maintenance, emergency repairs, and system upgrades. Budgeting proactively minimizes the financial impact of unexpected failures.

Review and Adjust Regularly

Periodically reassess the maintenance plan based on performance, emerging technologies, and regulatory changes. Continuous improvement ensures the system remains reliable and compliant.

Example Implementation

A corporate office implemented a quarterly inspection schedule and predictive monitoring on critical circuits. Within six months, they identified and addressed several aging panels and overloaded circuits, preventing a potential outage and saving thousands in equipment replacement costs.

Emergency Preparedness for Electrical Failures

- Why Businesses Need an Emergency Plan:- Unexpected electrical outages can disrupt operations, endanger employees, and damage equipment. An emergency plan ensures quick response, clear responsibilities, and minimal downtime during electrical crises.

- Key Components of a Plan:- Include backup power solutions, emergency lighting checks, surge protection, and staff training on shutdown procedures. Conduct drills periodically to test the plan’s effectiveness and make improvements.

- Real-World Example:- A retail store faced a sudden power outage during peak hours. Because they had an emergency response plan and backup generator, operations continued with minimal disruption, saving revenue and avoiding customer dissatisfaction.

Leveraging Technology for Smarter Electrical Maintenance

Predictive Analytics and Monitoring

Modern technology allows businesses to monitor current, voltage, and energy consumption in real time. Predictive analytics can forecast potential failures, helping prevent costly outages.

Smart Devices and IoT Integration

Smart panels, circuit breakers, and IoT-enabled sensors provide continuous insights into system health. Businesses can identify inefficiencies, detect anomalies early, and schedule maintenance more effectively.

Benefits of Tech-Driven Maintenance

Using technology reduces manual inspection costs, improves accuracy, and enhances overall system reliability. It ensures businesses stay ahead of potential issues while optimizing energy use.

Securing Your Business Against Electrical Failures Effectively

Regular commercial electrical maintenance is more than a preventive measure—it is an essential business strategy. Maintaining a robust, safe, and efficient electrical system minimizes the risk of fire, equipment damage, operational downtime, and regulatory violations. Proactive inspections, timely upgrades, predictive monitoring, and employee awareness contribute to a safer workplace, operational efficiency, and cost savings. Businesses that prioritize electrical maintenance safeguard not only their physical infrastructure but also their reputation, employee well-being, and financial stability.

At MDE Electric LLC, we bring 25

years of experience ensuring commercial properties operate safely and efficiently. Based in Milton, Florida, our team specializes in comprehensive electrical inspections, preventive maintenance, and upgrades tailored to the unique needs of businesses. We combine technical expertise with industry best practices to identify risks before they escalate and implement solutions that enhance safety, efficiency, and compliance. Partnering with us ensures your business receives professional, reliable electrical care, giving you peace of mind while protecting your employees, equipment, and operations.